- New method of manufacturing listed in ASTM A312 material specification (Heavily Cold Worked)

- Metallurgical equivalent of seamless

- Weld and Heat Affected Zone (HAZ) eliminated via PCC Rollmet Inc.’s patented Cold Roll Extrusion process (seam free)

- Corrosion tested by ASTM 249 – former weld/parent metal decay ratios of less than 1.0

- Corrosion tested to ASTM 262 practice A, B, C, E and F

- Lower cost than seamless

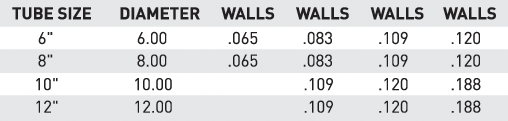

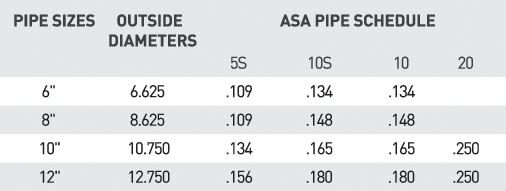

- Sizes 6” to 12” schedule 20, 10 and 5(s)

- Cold Roll Extruded solid-solution alloy pipes offer greater strength than conventional manufactured pipe/tube because of the fine grain size achieved through cold working and recrystallization

- Cold Roll Extrusion, as a net process, achieves final pipe dimensions through metal displacement with very little waste

- Cold Roll Extrusion is performed at ambient room temperature

- Cold Roll Extrusion utilizes precision stainless steel and nickel alloy blanks or extruded preforms as starting material for all stainless and nickel alloy production

- Isotropic properties can be achieved either as a cold worked tubular or in all finished annealed tubular products

- Enhanced corrosion resistance is achieved through ASTM 5 or finer grain size

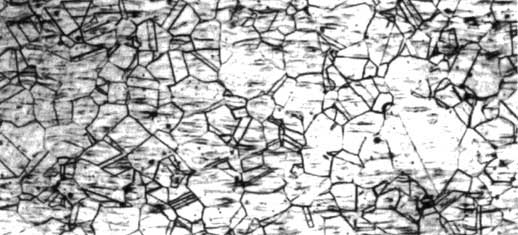

Parent metal area as received from mill.

Parent metal area after roll extrusion and anneal.

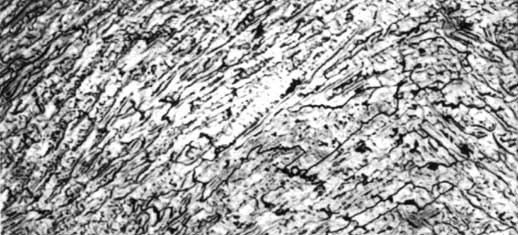

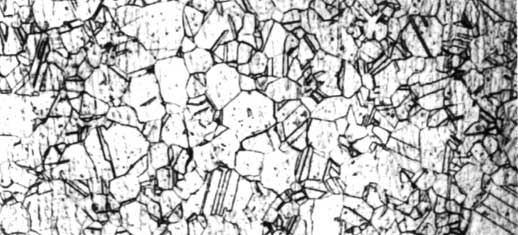

Weld metal area as received from mill.

Weld metal area after roll extrusion and anneal.

* Most diameter and light wall combinations of HCW tubes can be manufactured by PCC Rollmet, Inc.

- AS9100/ISO9001

- ISO 9001 approved

- AD2000-Merk