- Seamless Nickel Alloy pipe to ASTM/ASME B/SB 161, 163, 165, 167, 407, 423, 444, 622 & 729 specifications

- Seamless Nickel Alloy pipe meets ASTM/ASME B/SB829 dimensional requirements for cold worked pipe and tube

- Seamless Nickel Alloy pipe furnished in cold worked and or cold worked annealed condition

- 15 ft to 24 ft single random lengths – some sizes in 10 to 15 ft lengths

- Up to 40 ft lengths in CRA Casing and Line Pipe

- Minumum 35% cold work

- 50 years of manufacturing experience

- Cold Roll Extruded solid-solution alloy pipes offer greater strength than conventional manufactured pipe/tube because of the fine grain size achieved through cold working and recrystallization

- Cold Roll Extrusion, as a net process, achieves final pipe dimensions through metal displacement with very little waste

- Cold Roll Extrusion is performed at ambient room temperature

- Cold Roll Extrusion utilizes precision nickel alloy blanks or extruded preforms as starting material for all nickel alloy production

- Isotropic properties can be achieved either as a cold worked tubular or in a finished annealed tubular

- Enhanced corrosion resistance is achieved through ASTM 5 or finer grain size

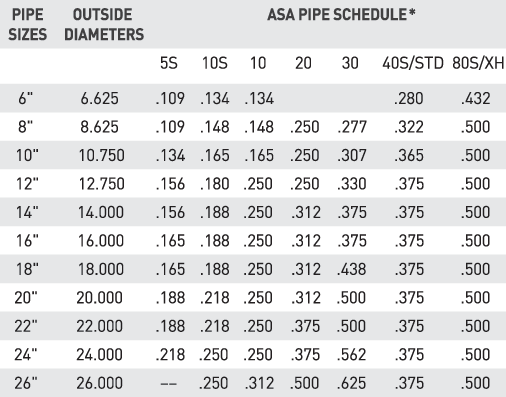

* Wall sizes available up to 1.5” on certain pipe sizes

- AS9100/ISO9001

- ISO 9001 approved

- AD2000-Merkblatt W0 approved