Forward Extrusion

Uses machined forging and extrusions and ERE product as starting material

The starting hollow is placed inside a one piece, cylindrical die ring. The rollers inside the starting hollow are displaced radially outward until they bite into the inside diameter of the hollow surface a controlled amount. The hollow outside diameter remains constant while the rollers produce a thinner wall with a corresponding increase in I.D. and hollow length in a single pass.

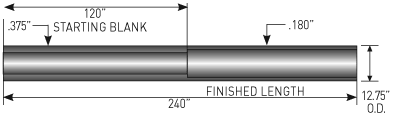

Internal Cold Roll Extruded cylinder typical starting blank, demonstrating material economy and axial growth in length while keeping the O.D. constant during Internal Cold Roll Extrusion.