Forward and Reverse Extrusion

Uses centrifugal castings, forgings and extrusions as starting material

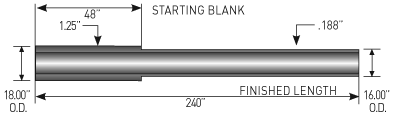

External Cold Roll Extrusion utilizes a mandrel over which the hollow is placed. Two (2) annular die rings are brought into position on the hollow. The mandrel and hollow are rotated while the die rings progress axially through a series of passes. This simultaneously reduces wall thickness and O.D. while the hollow grows in length. The I.D. remains constant.

External Cold Roll Extruded cylinder typical starting blank, demonstrating material economy and axial growth in length while keeping the I.D. constant during External Cold Roll Extrusion.

16" External Cold Roll Extrusion Machine

30" External Cold Roll Extrusion Machine

<

>